The smart Trick of Roar Solutions That Nobody is Talking About

The smart Trick of Roar Solutions That Nobody is Talking About

Blog Article

Some Known Factual Statements About Roar Solutions

Table of ContentsRoar Solutions for Beginners3 Simple Techniques For Roar SolutionsThe Ultimate Guide To Roar SolutionsFacts About Roar Solutions Uncovered

The tools register is a comprehensive database of tools documents that includes a minimum collection of fields to recognize each item's place, technological parameters, Ex-spouse classification, age, and ecological data. This details is important for monitoring and handling the devices efficiently within dangerous locations. On the other hand, for routine or RBI tasting evaluations, the quality will be a mix of Detailed and Close assessments. The proportion of Thorough to Shut inspections will certainly be figured out by the Equipment Danger, which is analyzed based upon ignition threat (the probability of a source of ignition versus the likelihood of a flammable ambience )and the hazardous location category( Area 0, 1, or 2). This variant will also affect the resourcing demands for work prep work. When Great deals are defined, you can develop tasting plans based on the example dimension of each Whole lot, which describes the number of arbitrary devices things to be inspected. To figure out the called for example dimension, 2 elements require to be reviewed: the dimension of the Lot and the group of examination, which shows the level of initiative that must be applied( lowered, normal, or boosted )to the assessment of the Lot. By integrating the classification of examination with the Great deal size, you can then develop the ideal denial requirements for a sample, suggesting the allowed variety of malfunctioning products discovered within that example. For even more information on this process, please refer to the Energy Institute Guidelines. The IEC 60079 common advises that the optimum interval in between evaluations need to not go beyond 3 years. EEHA assessments will certainly also be carried out beyond RBI projects as part of scheduled upkeep and devices overhauls or fixings. These evaluations can be attributed towards the RBI sample sizes within the impacted Whole lots. EEHA examinations are performed to determine faults in electric devices. A weighted racking up system is important, as a single piece of equipment might have several mistakes, each with differing levels of ignition risk. If the consolidated rating of both examinations is less than twice the fault rating, the Great deal is considered acceptable. If the Great deal is still taken into consideration inappropriate, it must undergo a complete inspection or reason, which might activate stricter assessment procedures. Accepted Great deal: The reasons for any kind of faults are determined. If an usual failure mode is found, additional tools might call for maintenance. Mistakes are categorized by seriousness( Security, Stability, House cleaning ), making certain that urgent problems are evaluated and dealt with immediately to reduce any type of influence on security or operations. The EEHA data source ought to track and tape the lifecycle of faults in addition to the restorative activities taken. Applying a robust Risk-Based Evaluation( RBI )technique is important for guaranteeing conformity and security in managing Electric Tools in Hazardous Locations( EEHA). Automated Fault Scoring and Lifecycle Monitoring: Easily handle faults and track their lifecycle to enhance examination accuracy. The intro of this support for risk-based inspection better strengthens Inspectivity's placement as a best-in-class service for governing conformity, in addition to for any type of asset-centric examination use case. If you want finding out more, we invite you to ask for a presentation and find just how our service can transform your EEHA administration processes.

With over one decade of mixed Ex experience (IECEx/ATEX, EEHA), Saipex started to advertise the importance of competence of all workers associated with the Hazardous Area area in 2019. In 2021, our partnership with IndEx and Tech Ability International (TSI) noted a turning point in the Saipex road to continue Ex-spouse improvement.

The smart Trick of Roar Solutions That Nobody is Discussing

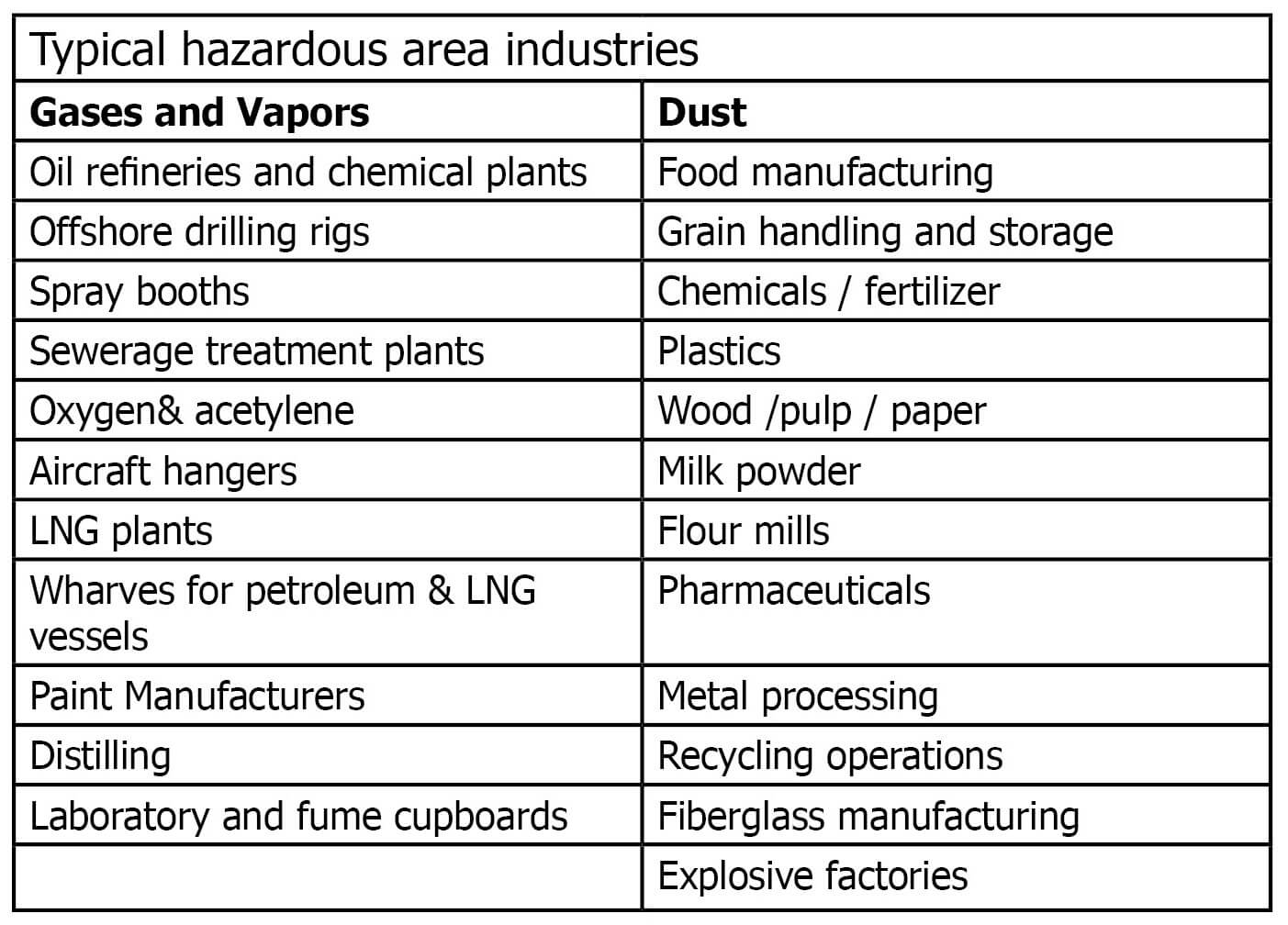

In terms of explosive risk, an unsafe area is an environment in which an explosive environment exists (or might be anticipated to be existing) in quantities that require special preventative measures for the building and construction, installment and use equipment. In this article we discover the difficulties faced in the work environment, the danger control steps, and the called for proficiencies to work safely.

(https://www.interweave.com/plus_old/members/roarsolutions/profile/)

These compounds can, in particular problems, form explosive ambiences and these can have significant and terrible repercussions. Many of us are acquainted with the fire triangle eliminate any kind of one of the 3 components and the fire can not take place, but what does this mean in the context of unsafe areas?

This is then verified through inspection and testing and is protected throughout the life of the setup by using the correct maintenance strategies, supplemented by periodic assessment. When all these procedures are taken, they should additionally be recorded. The verification file consists of information such as the harmful location category illustration, producers' documents, equipment accreditation, style illustrations and computations, inspection records, and records of an individual's proficiency and proceeding specialist development (CPD), such as through ECA's eCOMS software program.

The Best Strategy To Use For Roar Solutions

It is vital that pupils understand and have a thorough knowledge as to what specifically comprises a hazardous area. The trainee needs to additionally know why training is essential prior to trying to take on work or specifying devices into a harmful location. These areas are also referred to as categorized locations and are defined as areas which have a high probability of a surge as a result of the feasible existence of combustible gases, vapors, cleans and so on.

Industries which contain dangerous areas are now demanding that electric workers that are specifying or working in these areas ought to have a harmful area qualification that regards them competent. Jobs in these industries are really fulfilling so you require to be prepared. To fulfill this need for the industry, nationally recognised training in Certificate IV in Unsafe area Electrical and EEHA training on the advancement of knowledgeable specialists.

The Best Guide To Roar Solutions

Tech Skills Australia is a Registered Training Company giving you with the most affordable and quickest way in acquiring your certification - Roar Solutions. Our instructors are industry certified and have a number of years of procedure experience. Our programs have actually aided thousands of individuals from business supervisors to day-to-day staff members in acquiring a solid hold on this not so complicated yet high risk training

The training also consists of determining the dangerous locations, resources of explosion and the residential properties of harmful materials along with the responsibilities and features of all celebrations, policies, systems, standards and technique codes linked to dangerous areas. We provide instrumentation and unsafe location solutions that remain in compliance to newest AS/NZS and international sector requirements.

Report this page